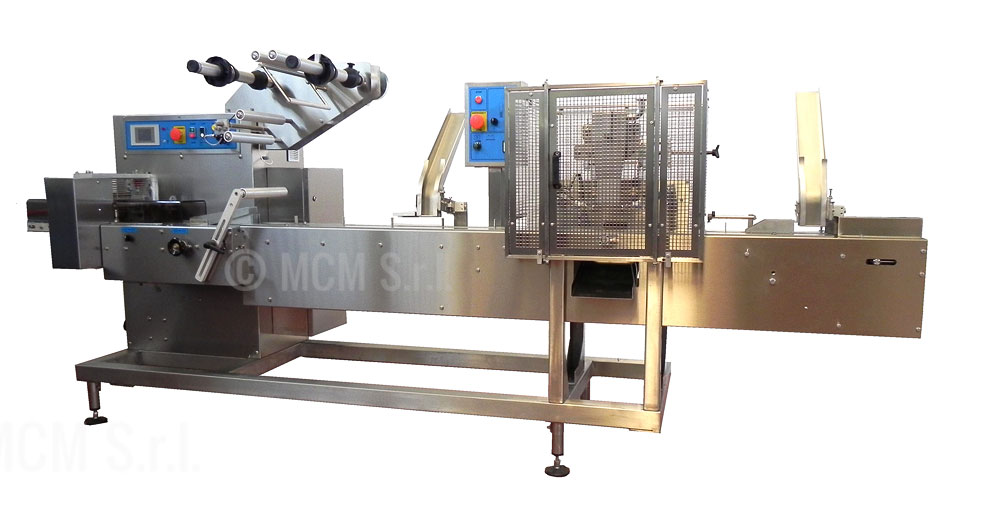

M100 SANDWICH machine is an automatic line to produce 5000 sandwich ice creams per hour, versatile and simple in set-up changing , it is able to produce square sandwiches, rectangular, round and mini sandwiches, with one or more ice cream colours.

Manufactured in stainless steel, coated steel and anodized aluminium, to be washed and sanitized in accordance with actual industrial ice cream rules.

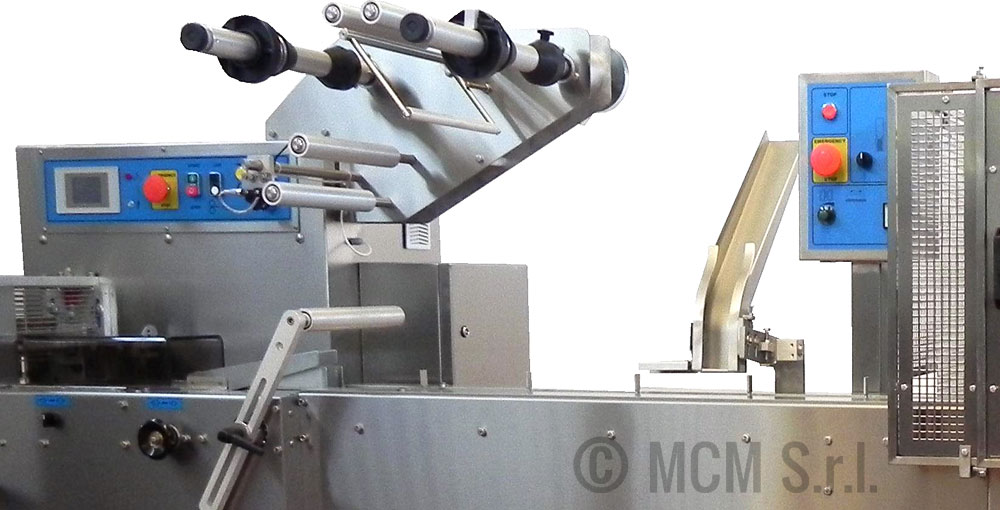

M100 SANDWICH is the cheaper of its range but at the same time it is technologically advanced, sealing rollers are motioned by Brushless servo motor, picture in place is automatic and integrated in the servo drive, the wire cutting device is also independently motioned by brushless servo motor, so less mechanical driving means low maintenance. The same to bigger models it is fitted with "no slice no biscuit" device which allows to expel the ice cream slice if the lower biscuit is not present.

Working with films in biorientate polypropylene, coextruded and/or lacquered, several coupled materials, hot sealing or cold having thickness 20 up to 40 μm, neutral ,continuous printing and picture in place.

Standard equipment

- Double reel holder

- Simple cutter jaws

- Fixed folding box

- One format included

- Picture in place device

- Two pairs of sealing rollers motioned by Brushless servo moto

- Mechanical cutting jaws speed variator

- AC line motor controlled by inverter.

- Wire cutting device with two ark motioned by Brushless servo motor

- Biscuits cartridges pneumatically liftable

- Funcionings controlled by integrated drives logical

- Digital thermostats

Optionals

- Additional format

- Rotating data printer

- Embossing date coding